Truly Shocking: The Uses and Applications for A Thermal Shock Chamber

June 29, 2023From automotive safety testing to space exploration, thermal shock chambers have been used in a variety of industries and applications. Thermal shock chambers can rapidly change temperatures from one extreme to another while subjecting materials or components within the chamber to a wide range of different temperatures.

This article will explore how these temperature-shifting chambers can be utilized for various purposes, some of which may seem truly shocking.

We’ll examine why thermal shock is important for certain processes and what it means when something can withstand such conditions.

Finally, we’ll discuss how this technology has shaped current research and development initiatives across many diverse fields. Read on to find out more about the uses and applications of thermal shock chambers!

Overview of Thermal Shock Chambers

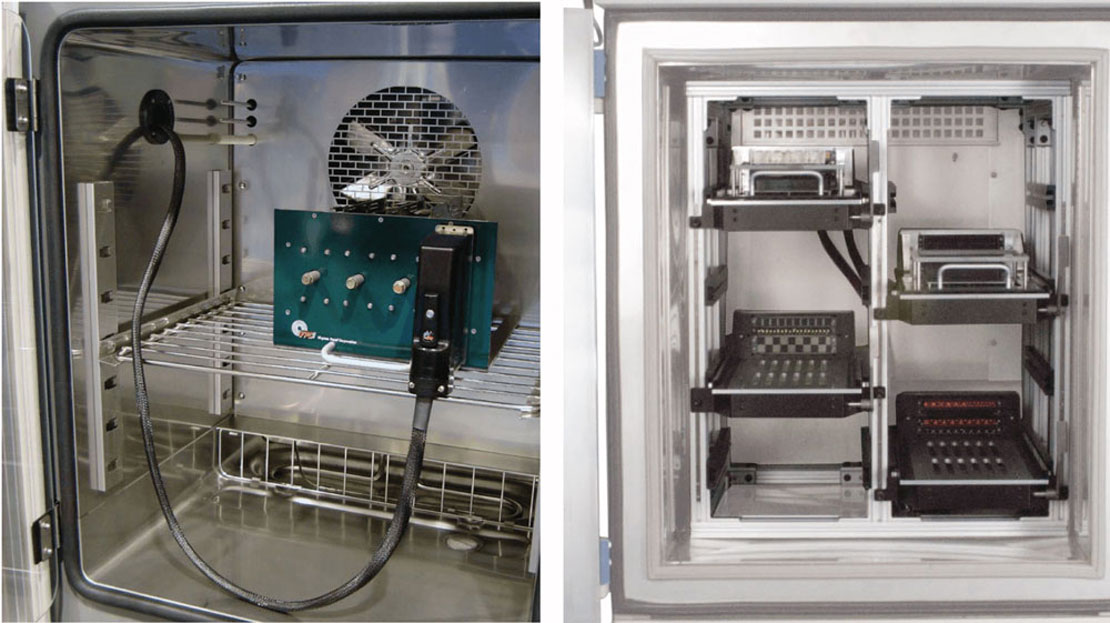

Source: www.vpc.com

Thermal shock chambers are invaluable tools for testing the durability of many different kinds of materials and components. Used in a variety of industries, these chambers offer an efficient way to simulate real-world conditions on a wide range of products.

From aerospace parts to consumer goods, thermal shock chambers allow manufacturers and suppliers to rapidly test their products while ensuring that they remain structurally sound over time and under extreme temperatures.

By understanding the effects of sudden temperature changes on their products, companies can better ensure safety and reliability for consumers.

In this overview we will explore how thermal shock chambers work, the types available today, as well as some common applications where they are used.

Benefits of Utilizing a Thermal Shock Chamber

Thermal shock chambers provide many benefits for a variety of industries. These devices are designed to rapidly cycle between hot and cold temperatures, which can be used to test the strength and durability of materials.

This testing is invaluable in fields such as aerospace engineering, automotive manufacturing, defense applications, and pharmaceuticals. Using a thermal shock chamber provides several advantages over traditional methods of stress testing materials.

It eliminates the need for multiple pieces of equipment since all temperature changes occur within the same chamber. In addition, it’s much faster than other forms of thermal cycling, significantly reducing time spent on product development cycles or research experiments.

Another benefit is that testing can take place at extreme temperatures both high (up to 500°C) and low (-85°C). This allows engineers to simulate conditions found in some environments more accurately than ever before possible with traditional methods.

The versatility offered by this technology allows manufacturers to conduct reliable tests quickly while ensuring safety protocols are met due to precise control over temperature changes within the chamber itself.

Finally, utilizing a thermal shock chamber also helps reduce costs related to material failure or waste due to faulty products during production runs as results from these tests allow manufacturers/researchers to identify any weak points ahead of time so they can be addressed prior to releasing them into the market or field use respectively

Potential Uses and Applications for Thermal Shock Chamberss

Source: intertek.com

Thermal shock chambers are uniquely versatile tools that have a wide variety of potential uses and applications. From testing the durability of materials to researching the effects of extreme temperatures on electronics, thermal shock chambers can be utilized in many different fields.

In manufacturing, thermal shock chambers are often used to test products for their ability to withstand heat-related damage over time. By exposing products to sudden and drastic temperature changes, manufacturers can gain insight into how their products will hold up once released into the market.

This helps prevent costly recalls due to defective merchandise later down the line. In automotive engineering, thermal shock tests are conducted on engines or other components with high levels of stress placed upon them during use.

By simulating temperature shifts through rapid heating and cooling cycles within a thermal chamber, engineers can gauge how well an engine or part can handle difficult driving conditions such as speed fluctuations or harsh terrain.

Thermal shock chambers also have valuable medical applications in hospitals and research laboratories across the world ranging from evaluating drug effectiveness at various temperatures up to cryopreservation techniques for organ storage and transplantation surgery preparation.

In addition, by controlling temperature along with humidity levels in a controlled environment it’s possible for researchers studying plants or animals under varying climate conditions to simulate those same environmental settings without having any physical access outside their laboratory walls!

Safety Considerations

When it comes to operating a thermal shock chamber, safety is of the utmost importance. It’s important to know what kind of hazards may present themselves during operation and how to mitigate those risks.

Temperature control is key when it comes to using a thermal shock chamber; too high a temperature can cause harm or damage both inside and outside the chamber. Operators must be aware of any potential overheating issues before they begin work in the chamber.

Additionally, because these chambers contain hazardous materials such as flammable liquids, strict protocols must be followed regarding their handling and storage. Finally, users should ensure that proper ventilation is installed for exhaust gases from the unit to safely exit the facility without endangering anyone inside or outside.

In short, by following these guidelines and taking all necessary precautions while operating a thermal shock chamber, workers can stay safe at all times while still enjoying its many benefits.

Source: www.associatedenvironmentalsystems.com

Conclusion

Thermal shock chambers provide a unique and powerful tool that can be used for a variety of applications. From testing the strength and durability of materials to simulating extreme temperatures, thermal shock chambers are an invaluable resource in various industries.

The ability to simulate rapid temperature shifts allows customers to perform tests accurately and with confidence, ensuring their products meet the highest standards of quality.

Thermal shock chambers have become increasingly popular as technology has advanced, allowing businesses to test their products more effectively than ever before.