Safety Protocols and Best Practices for Operating Laser Machines.

August 24, 2023 0 By Diane BooneOperating laser machines is an essential part of modern manufacturing and engineering. However, it requires a great deal of caution and expertise to ensure that safety protocols are followed strictly.

In this article, we will discuss the safety protocols and best practices for operating laser machines in order to keep workers safe while maximizing efficiency. Well also explore the various risks associated with improper operation of these machines so that you can take necessary precautions in your own setup.

With the right knowledge and safety measures, you can operate these powerful tools safely and effectively – ensuring both quality results and peace of mind.

Wear Appropriate Protective Wear and Eye Protection

Source: www.thefabricator.com

It is essential for workers who use laser machines to wear appropriate protective gear and eye protection. Protective clothing should include long-sleeved shirts, pants, and closed-toe shoes that cover the entire foot.

A face shield or goggles must be worn to protect eyes from stray lasers and splashes of hot material. Workers should also ensure that their hair is securely tied back before operating any machinery in order to prevent it from coming into contact with moving parts.

In addition to wearing proper safety attire, workers should adhere strictly to all safety protocols provided by the manufacturer of the machine they are operating, such as keeping flammable materials away from the work area and never exceed recommended power levels when using a laser cutting system. Following these steps ensures a safe workplace environment and reduces risk of injury or property damage due to equipment malfunctions or improper use

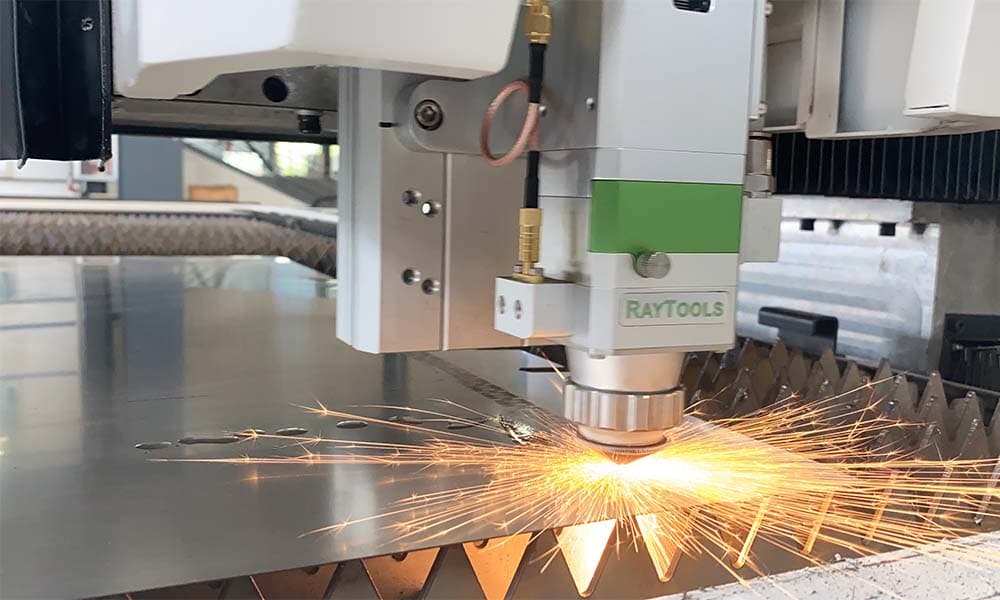

Follow Manufacturer Instructions for Proper Operation of the Machine

Source: www.canadianmetalworking.com

When it comes to the safe operation of laser machines, it is essential to adhere to the manufacturers instructions for proper use. This includes following all safety guidelines provided by the manufacturer and adhering to any operating protocols required when using the machine.

It is also important to ensure that operators are properly trained on how to operate the equipment before allowing them access. Additionally, tools should be inspected prior to each use and kept in good condition at all times in order to maximize their lifespan and minimize risk of injury during operation.

Finally, protective eyewear should always be worn when working with lasers as a precautionary measure against potential damage from light radiation exposure. By following these basic steps, laser machine operators can help ensure their safety while enjoying reliable performance from their equipment over time.

Keep All Electrical Components Away from Water Sources

Source: www.amazon.com

In order to ensure that laser machines remain safe while in operation, it is essential to keep all electrical components away from sources of water. Not only can direct contact with water cause electric shock and other potential safety hazards, but even the presence of too much humidity can damage sensitive electronic parts.

This means keeping any power cords or plugs far enough away from sinks, fountains, or other sources of moisture. Additionally, make sure that no devices are left in areas where they could be exposed to condensation during temperature changes.

Finally, if you need to clean your laser machine’s exterior surfaces for aesthetic purposes or otherwise, use a dry cloth and never allow liquids near the interior wiring and circuitry. Strict adherence to these protocols will help maintain the safety of everyone using laser machinery.

Maintain a Safe Distance from the Laser at All Times During Operation

Source: www.medicalnewstoday.com

When operating a laser machine, it is essential to maintain a safe distance from the laser at all times. This will reduce the risk of injury or damage caused by exposure to high-powered and potentially hazardous lasers. It is recommended that workers stay at least 6 feet away from any active lasers while on the job site.

Additionally, any protective gear should be worn when working in close proximity with the laser device, including safety glasses and gloves. Its also important for operators to be aware of their surroundings and avoid placing themselves or anyone else in danger by getting too close to an active laser beam.

When transporting lasers, machines should always be turned off and placed into secure containers until they can safely reach their destination without putting anyone in harms way. Finally, if an operator notices anything irregular while using a laser machine—such as a sudden change in its performance—they should immediately discontinue use until further inspection can take place.

Conclusion

Source: www.laser-cutting-ipg.com

When it comes to operating laser machines, safety is of the utmost importance. Adhering to best practices and protocols when using these powerful tools can help ensure a safe and successful operation.

It is essential that operators are aware of all safety regulations associated with their specific laser machine. Additionally, they should always wear proper protective gear such as goggles or face shields while in use, and be sure to unplug the machine before making any adjustments or repairs.

Following these simple steps will go a long way towards keeping everyone safe while using Laser Machines.