Lights and Lasers: A Future of the Welding Industry?

June 24, 2023As technology advances, the welding industry is no exception. From traditional methods of welding to more modern practices, the future of this field looks promising.

One such development in welding is the emergence of lights and lasers for use in joining two pieces together or for cutting through material with precision. This article will explore how these tools have changed and enhanced the welding process, as well as what potential applications they may have going forward.

Well also look at some examples of their use in different industries and discuss why they could be important to the future of welding.

The Benefits of Utilizing Lights and Lasers in Welding

Source: www.cavitar.com

Lights and lasers are becoming increasingly popular in welding for many reasons. For one, they can create a much more precise weld than traditional arc welding methods.

This precision eliminates potential errors that could result from human error. Furthermore, lights and lasers enable the welder to work with thinner materials, as well as those that are difficult to access due to their small size or shape.

Additionally, these technologies can be used at higher speeds than traditional methods while still maintaining a high level of quality control over the welds produced. Moreover, utilizing lights and lasers in welding offers several safety benefits for workers as well.

As mentioned before, because of its precision it reduces the risk of mistakes which could lead to serious injury or even death on the job site. In addition, these technologies reduce exposure time by enabling faster production cycles which means less physical strain on workers during long hours spent welding on a project – making it easier for them to remain productive without compromising safety standards or risking harm from overexertion.

Finally, there is also evidence that laser beams may be able to detect flaws within metal parts prior to welding which further ensures safety throughout each projects completion process. It is clear that utilizing lights and lasers has many advantages when it comes to improving both accuracy and productivity in the field of welding – not only does this technology allow welders greater flexibility when working with different materials but it also increases overall safety levels significantly too! As such, incorporating modern lighting solutions into current processes appears set to become an integral part of future success within this industry – one which could prove invaluable for years ahead!

Exploring the Possibilities of Light and Laser Technology in Welding

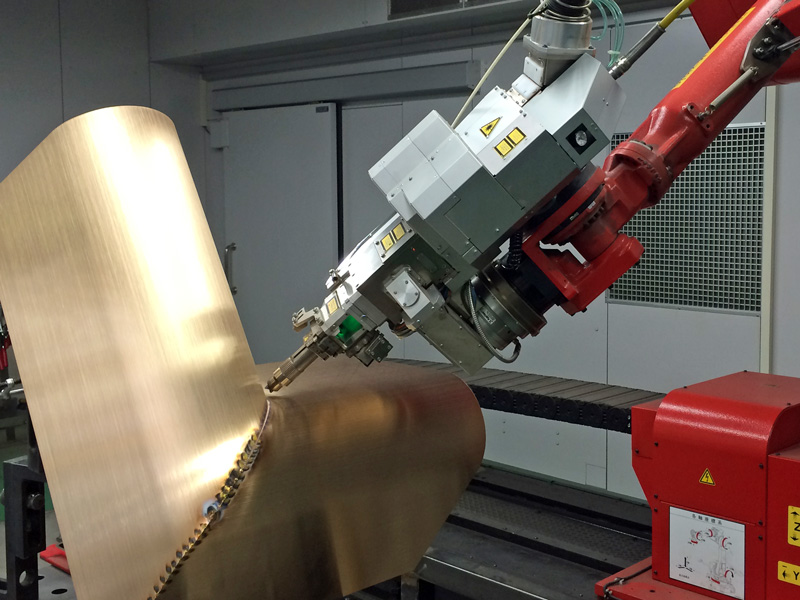

Source: www.kikukawa.com

The use of light and laser technology in welding is a relatively new concept, but one that has already made a huge impact on the industry. Not only does it allow for greater precision than traditional welding techniques, but it also allows welders to work faster and complete more complex projects with less effort. With the advances in this technology, there are seemingly endless possibilities when it comes to what can be achieved with welding.

From intricate designs and patterns to large scale structural welding jobs, light and laser technology have opened up an entirely new world of possibility for welders around the globe. Light and lasers provide numerous advantages over traditional forms of welding such as arc or spot-welding through their ability to create strong bonds without requiring high temperatures or complicated equipment.

They’re particularly useful in small spaces where access is limited or restricted due to size constraints; they can even reach angles that would otherwise be impossible using traditional methods. Furthermore, these tools are incredibly versatile: they can handle both ferrous metal alloys as well as non-ferrous metals like aluminum – something which other types of welders may struggle with.

Not only do light and lasers offer an incredible range of potential applications within the field of welding itself, but they also open up opportunities for other industries too – most notably 3D printing where accuracy is key. Lasers can be used not just to join components together but also cut them – allowing users unprecedented freedom when designing models from scratch rather than relying on pre-made parts or templates found online.

Its clear that light and laser technologies have revolutionized not just the way we approach welding tasks today but how we think about potential applications going forward into the future too – making them essential tools for any serious welder regardless if their projects are small scale hobby pieces or large industrial structures alike!

Understanding How Lights and Lasers Impact the Future of Welding

Source: www.thefabricator.com

As the welding industry moves into the future, understanding how lights and lasers can improve outcomes is essential. Lights and lasers both have unique advantages that can be beneficial in a variety of ways.

With their increased accuracy and precision, they are helping to redefine what it means to weld effectively. Lights provide greater visibility while welding in darker areas or on more intricate projects; laser beams allow for precise control over where heat will be distributed within the joint, making it easier than ever to create high-quality welds with minimal effort.

Lasers also increase speed by allowing multiple passes at once, eliminating any need for rework due to inaccurate placement or other issues associated with traditional methods of welding. In addition to being incredibly accurate and fast, lights and lasers also offer a wide range of safety benefits as well.

By using these tools instead of traditional methods, operators are able to reduce exposure time significantly which helps protect them from potential hazards like intense heat or toxic fumes caused by burning metal particles. Additionally, these tools eliminate the risk posed by sparks flying away due to improper technique or poor angle adjustment when working with steel components – something that often happens when using handheld torches for certain types of jobs.

The combination of improved accuracy and safety makes lights and lasers valuable additions to any welding operation looking for an edge in terms of productivity and quality assurance. As technology continues its march towards innovation in this field, theres no doubt that understanding how these new tools work will become increasingly important – making sure youre up-to-date on all developments is key if you want your business operations running smoothly now as well as into the future!

Conclusion

The welding industry has long been reliant on traditional methods of producing welds. However, with the recent development of lights and lasers, it looks as if the future of welding will be determined by these new technologies. Lights and lasers offer faster speeds, improved accuracy and decreased costs that are not achievable with other techniques, making them a great choice for many applications in the welding industry.

As more companies invest in this technology they can expect to achieve higher levels of productivity while also reducing their operational costs significantly. It is clear that lights and lasers have an important role to play in shaping the future of welding production, which could lead to increased safety standards as well as greater efficiency within this sector.